References

References

For the highest requirements

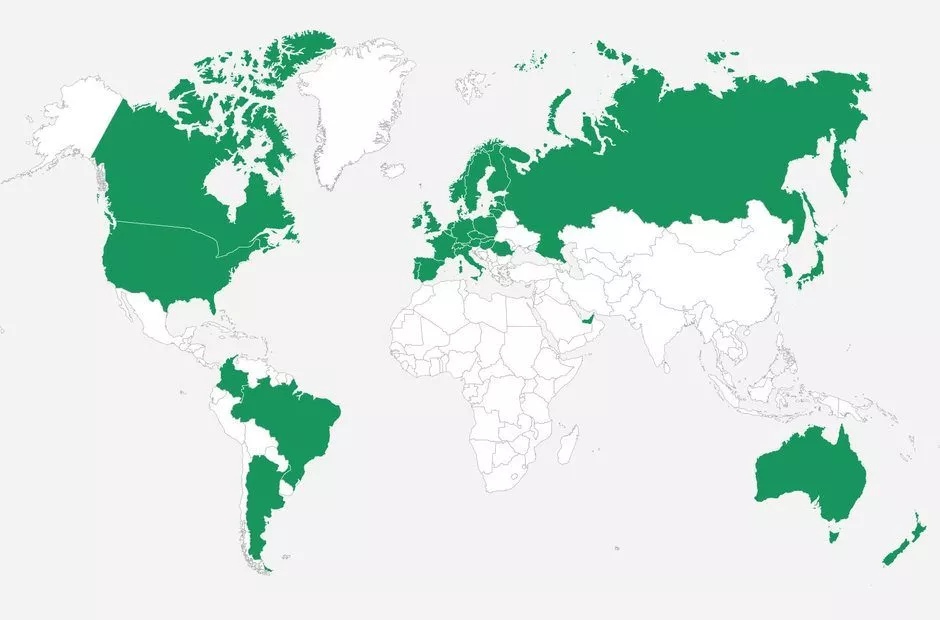

Brandenburger has already installed its pipe liners in more than 40 countries. Here is a small selection:

Mit der COLLAS-Gruppe in Lille / Nordfrankreich

Heute möchten wir Sie nach Lille in den Norden Frankreichs mitnehmen. Dort haben wir unregelmäßige, veraltete Leitungen vorgefunden, die bereits mehrfach repariert und ausgebessert wurden und so die Ist-Situation im ohnehin ungleichmäßigen, da gemauerten Kanal, verstärkt

haben.

Die Lösung: ein insgesamt 98 Meter langer BB2.5 DN 1300, der sich dank gefalteter Innenfolie optimal an die herrschenden Gegebenheiten angepasst und zu einem perfekten Ergebnis geführt hat.

An dieser Stelle Dankeschön an das großartige Team von COLAS für die hervorragende Vorbereitung und Organisation der Baustelle sowie die reibungslose Zusammenarbeit.

Mit UAB Pozemines Linijos in Littauen

„Sveiki“ aus Litauen. Bereits im April ging es gemeinsam mit Artūras Račkauskas von Poli und Georgi Barzanov und Marc Albrecht von ProKASRO Mechatronik GmbH auf Roadshow durch Litauen.

Insgesamt wurden in 5 Städten (Kaunas, Klaipėda, Šiauliai, Panevėžys, Vilnius) in Summe sechs BB2.5VERTICAL Schachtliner eingebaut und interessierten Vertretern aus Politik, Versorgungsbetrieben und Ingenieurbüros vorgeführt.

Wir sind stolz mit UAB

Požeminės Linijos, einem unserer langjährigsten und treusten Kunden, auch für die Schachtsanierung mit dem BB2.5VERTICAL einen strategischen Partner für die Marktentwicklung in Litauen gefunden zu haben. Die installierten Schachtliner sind die ersten UV-Schachtliner im ganzen Baltikum und UAB Požeminės Linijos ist die einzige von uns zertifizierte Einbaufirma im Baltikum.

Mit VALENTIN Environnement in Dunkerque

Die französische Stadt Dunkerque (Dünkirchen) ist zweifellos bekannt. Nahe der belgischen Grenze gelegen, ist sie mit rund 90 000 Einwohnern eine der wichtigsten Hafenstädte Frankreichs.

Ganze 3 Monate Vorarbeit an den Leitungen waren notwendig, um eine der Hauptleitungen der Stadt für die Sanierung vorzubereiten. Der Einbau unseres Liners BB2.5 mit DN 1150 und einer Gesamtlänge von 69 Metern ist der erste von insgesamt 6 Linern BB2.5 die zur Sanierung verbaut werden.

Besonders erwähnenswert ist die Gesamtgröße des Projekts, die umfangreiche Vorarbeit zur Sanierung sowie die wie immer sehr gute und partnerschaftliche Zusammenarbeit mit VALENTIN TP und der erfahrenen Sanierungsmannschaft. DANKE!

Betreuende Kollegen beim Einbau letzte Woche vor Ort: Carlo Murinni (Vertrieb Frankreich und Italien) sowie Ronny Siegel und Rico Schwabe (Anwendungstechnik).

Mit Swietelsky-Faber Kanalsanierung in Ettlingen

Vor der imposanten Kulisse des Schlosses Ettlingen und ohne den Personenfluss in der belebten Fußgängerzone zu stören, sind Ende April 2023 zwei Schächte mit dem Schachtliner BB2.5VERTICAL saniert worden. Die beiden 4 Meter tiefen Schächte in offener Bauweise zu erneuern war für die Stadt keine Option und so kamen einige der vielen Vorteile des BB2.5VERTICAL zum Tragen: geringer Platzbedarf auf der Baustelle, verzichtbare Wasserhaltung, schnelle Baustelleneinrichtung, wenig Lärm und Schmutz, Kürze der Baumaßnahme und damit wenig Auswirkung auf Zulieferverkehr und grundsätzlichem Verkehrsfluss.

Beschädigte Schachtringe sowie Korrosionsschäden an der jeweiligen Berme erforderten einen weiteren Vorteil des BB2.5VERTICAL: Sanierung des Schachtes bis zum Gerinne und inklusive der Berme. Kennwerte und Material entsprechen dem BB2.5, durch veränderte Beschaffenheiten des Glases ist der Schachtliner jedoch enorm dehnfähig, ermöglicht die Anpassung an die jeweilige Schachtgeometrie und macht aufwändiges Ausmessen im Vorfeld überflüssig. Christian Baeßler vom Stadtbauamt Ettlingen zeigte sich zufrieden ob des reibungslosen Ablaufs bei optimalem Ergebnis.

Mit Tucker & Sons stark vertreten in Australien

Gleich vierfach kam der BB2.5VERTICAL im Rahmen des Yarra Valley Water Projects mit M Tucker & Sons, unserem zertifizierten Einbauer und starkem Partner vor Ort, zum Einsatz. Alle 4 Einsatzorte befanden sich in ökologisch sensiblem Gebiet. Die Hauptleitung erforderte aufgrund sehr hoher Schwefelwasserstoffgaswerte besondere Vorsicht und auch das dort herrschende Wetter mit sehr hohen Regenmengen stellten die Einbauer vor große Herausforderungen.